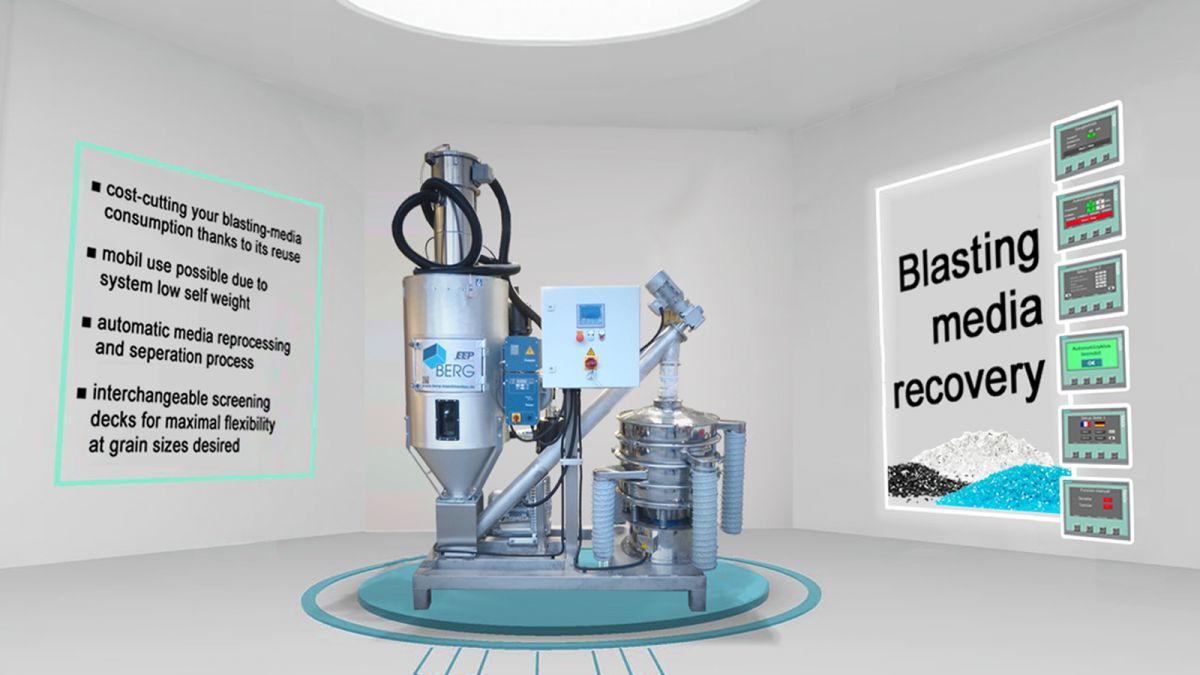

Model GM-150

Blasting-media recovery machine – mobile deployable as well

Automatic suction & screening system for the drying and reprocessing of blasting-media which is used in cryogenic deflashing machines

Cutting-costs by reuse of blasting-media – for the sake of our environment!

During the cryogenic deflashing, there is an accumulation of fine dust taking place coming from the molded articles being treated by the blasting agent. This dust accumulation impaired the performance data and it’s wearing off the jet-blasting quality more and more. In order to ensure a constant statistically reliable and economical processing, this contamination has to be removed from the granules at a certain point in time. Consequently, this blasting-media is sucked out of the cryogenic deburring system and new media is filled back. The contaminated granules are then often simply thrown away, although most of them can be reused!

To save costs in your blasting-media consuption, we are glad to offer you our solution:

Our automatically working blasting-media recovery machine consists of a suction & drying system and a vibrating-screen unit. The used blasting-media is sucked out of the deflashing machine via a suction hose. The drying of the polluted cold grains takes place in the suction tank and then are cleaned and separated into the appropriate grain sizes using the integrated vibrating sieve. In doing so, the reusable grain fraction and residual waste are separated.

Our standard version includes screening for the common used grain sizes of 1 mm, 0.75 mm and 0.5 mm (0,039 in., 0,029 in. and 0,019 in.). Further more, the screen deck perforation size can be changed individually as required and additional screen decks can be integrated (also retrospectively) as well.

Thanks to its low weight and slim design, this blasting-media recovery system can be used on the move and is also ideally suited for cryogenic deburring systems from other manufacturers.

Features

automatic aspiration, drying and separation of to be reporcessed blasting-media

equipped with integrated high-performance aspiration system and multi-deck vibration sieve

processing volumen up to about 130 litres (33 UK gal.) per cycle (on option bigger treatment volumes possible)

standard seperation into common used grain sizes 1 mm, 0,75 mm and 0,5 mm (0,039 in., 0,029 in. and 0,019 in.), other grain sizes screening possible by choice

interchangeable screen-perforation and integrable additional screening decks for maximum flexibility

antistatic reprocessing with 5 meter (16,4 ft) suction hose (other lenghts available on demand)

easy work-flow with comfortable Siemens touch panel operation

on special request: integration of your already existing vibrating sieve (where possible)

stationary or mobile use possible thanks to low self-weight and slim design

universally usable eventually for similar tasks as well- suitable also for cryogenic deflashing systems of other brands

Reduce your costs for blasting-media and avoid unnecessary waste – through reuse of your grains