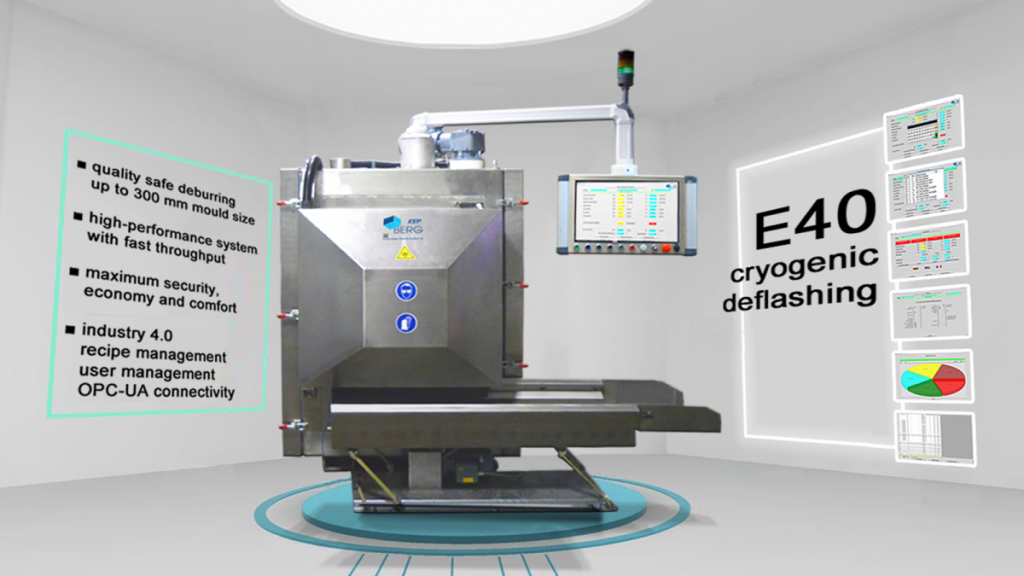

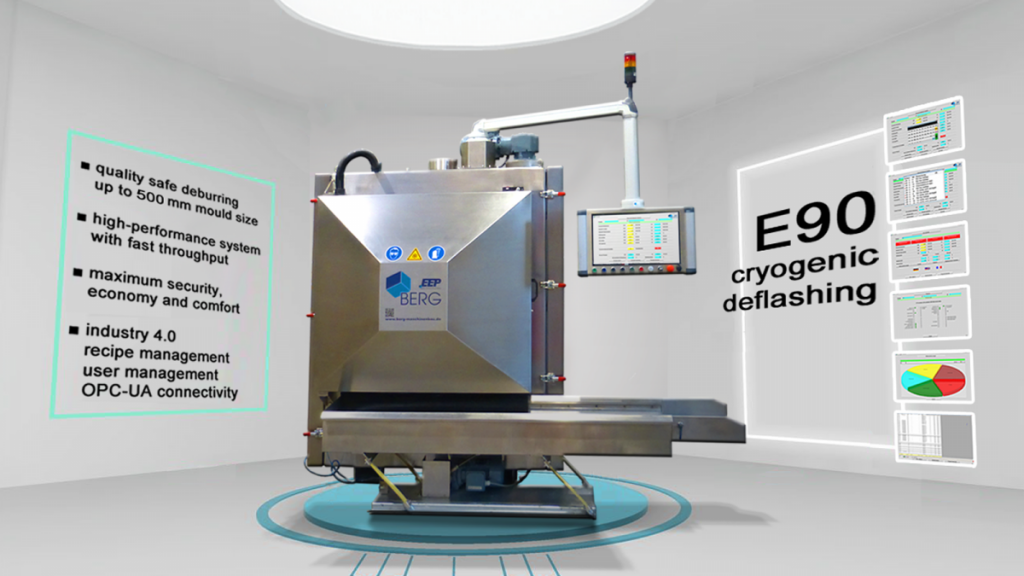

cryogenic deflashing machines

Benefit from more than 40 years of experience in cryogenic deflashing

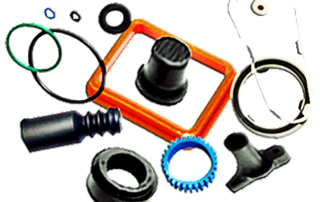

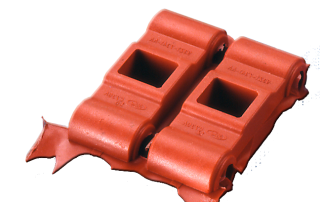

articles suitable for the cryogenic removing of burrs

elastomers

duromers

plastomers

zinc die-cast

elastomer-metal-bonds

other thermally embrittling materials

The process of cryogenic deflashing

For the freezing procedure of the batch, ultra-low temperature tiny drops of liquid nitrogen are injected to the loaded parts. During the nitrogen’s fast physical state conversion from liquid to gas, the extracted energy causes shock-freezing of the burrs which reach the embrittled condition immediately. The respective moulded parts still remain rest-elastic, therefore no damages from coolness tension can take place. The shock-frozen burr – not solid and elastic as the moulded part itself – can now be removed with high efficiency by the jet energy of blasing media.