3-D printing service

unprecedented opportunities thanks to newest 3D-print technology:

whether ultra-stable up to 103°C/217,4°F heat-resistant plastic parts or elastical silicone up to 65 shore – we can meet your very special needs on a wide range – with a print resolution of up to 15 μm!

whether ultra-stable up to 103°C/217,4°F heat-resistant plastic parts or elastical silicone up to 65 shore – we can meet your very special needs on a wide range – with a print resolution of up to 15 μm!

Realizing ideas quickly: we print your prototypes, devices, models, sales samples, artworks or even final products made of plastics or silicone. For your individual 3d-print, we need your data-model in STEP- or STL-format.

We are looking forward to your inquiries!

application, examples & ideas

planning & conception…

■ choose between various design proposals after inspecting the printed models

■ identify problems with true-to-scale 3d-model on current products

■ check grip sizes with the help of 3d-models

design…

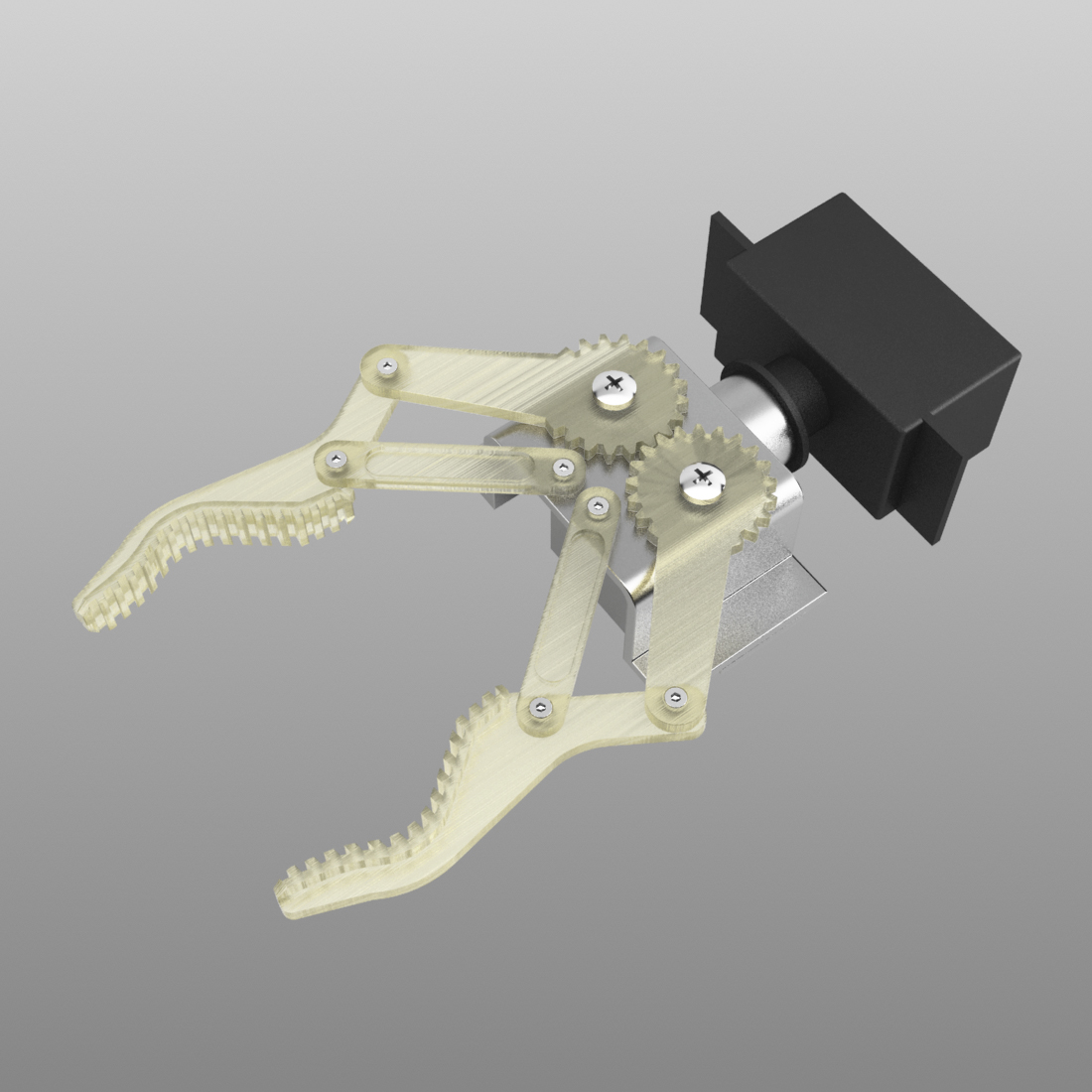

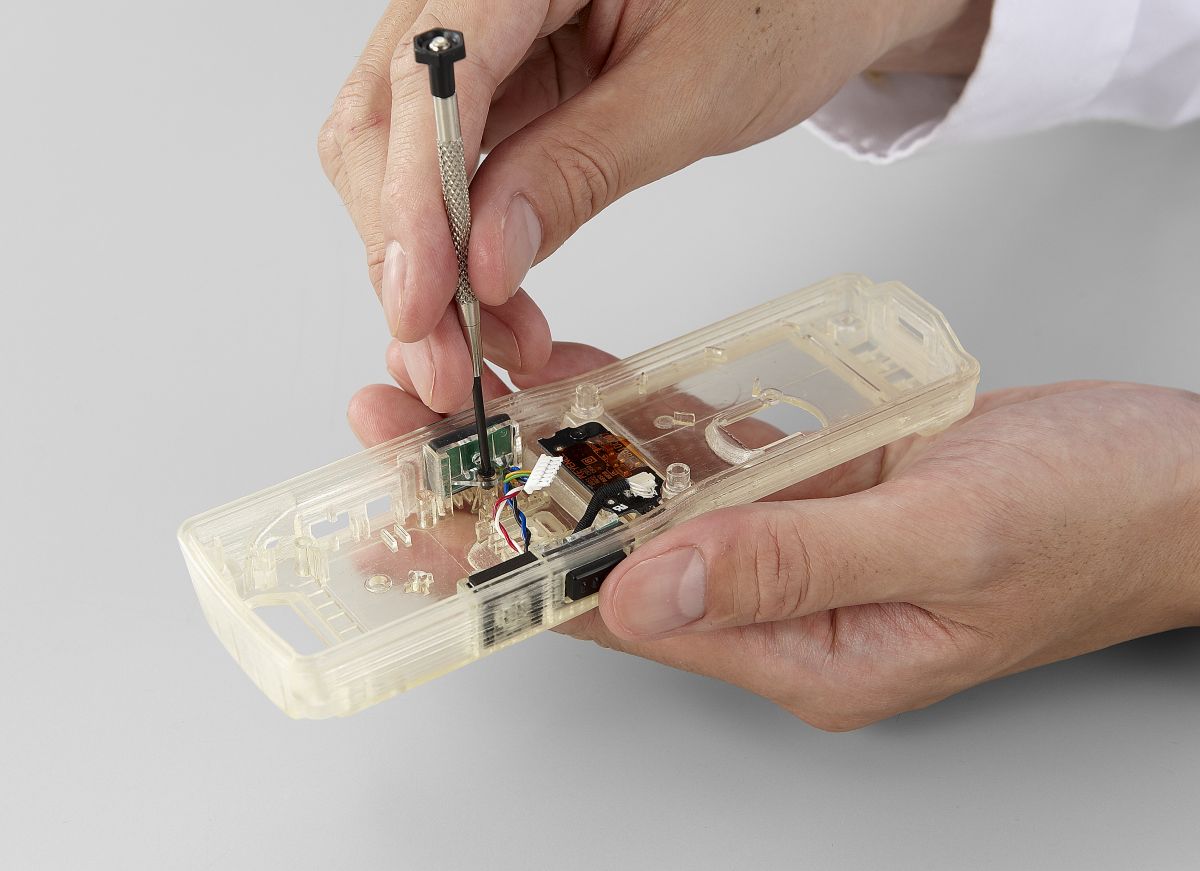

■ check in advance if products with complex mechanisms can be mounted without any problems

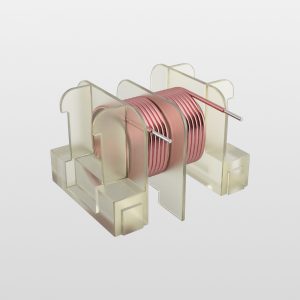

■ create designes where cable laying can be considered

■ explore snap-in locks as an alternative to screws

verifying & valuation…

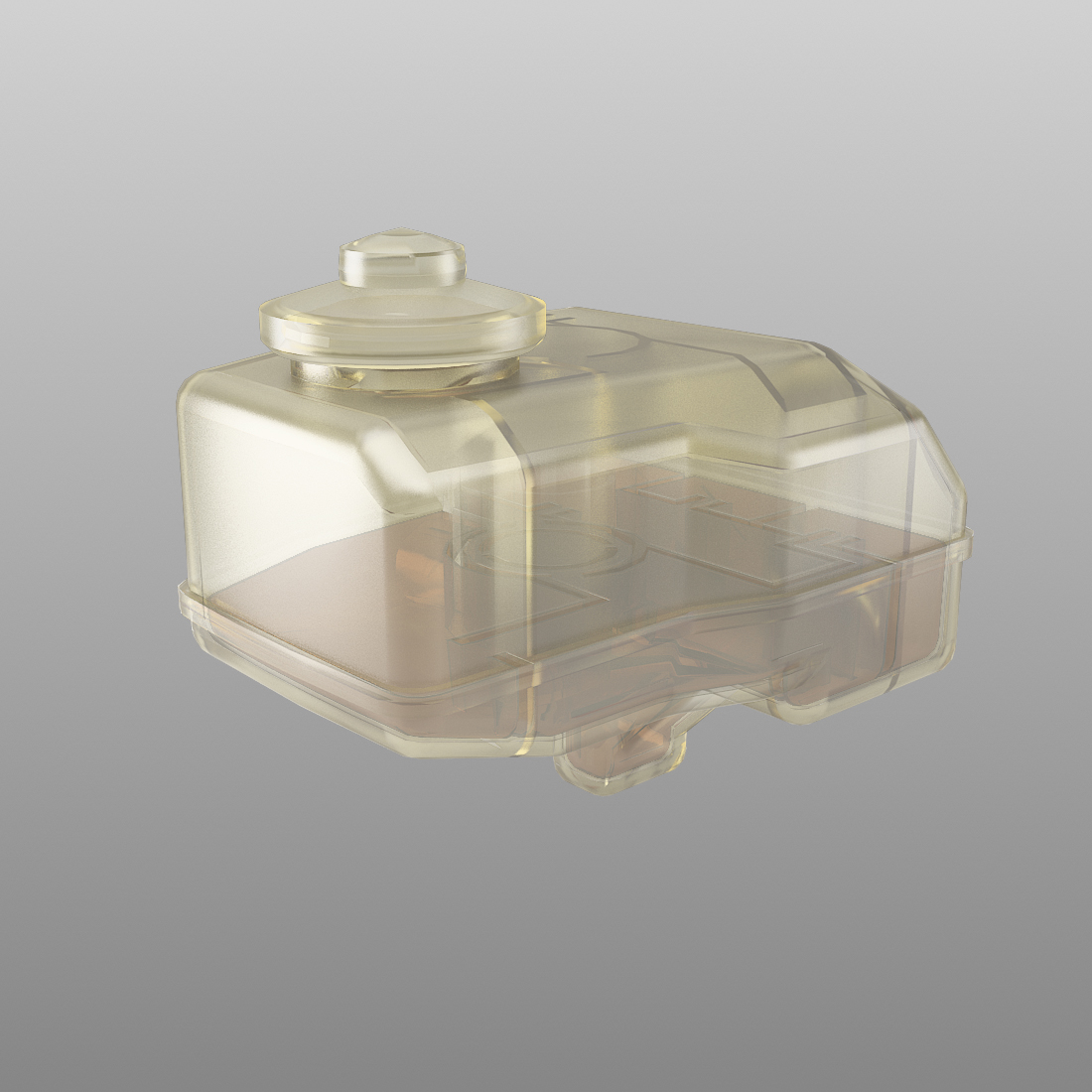

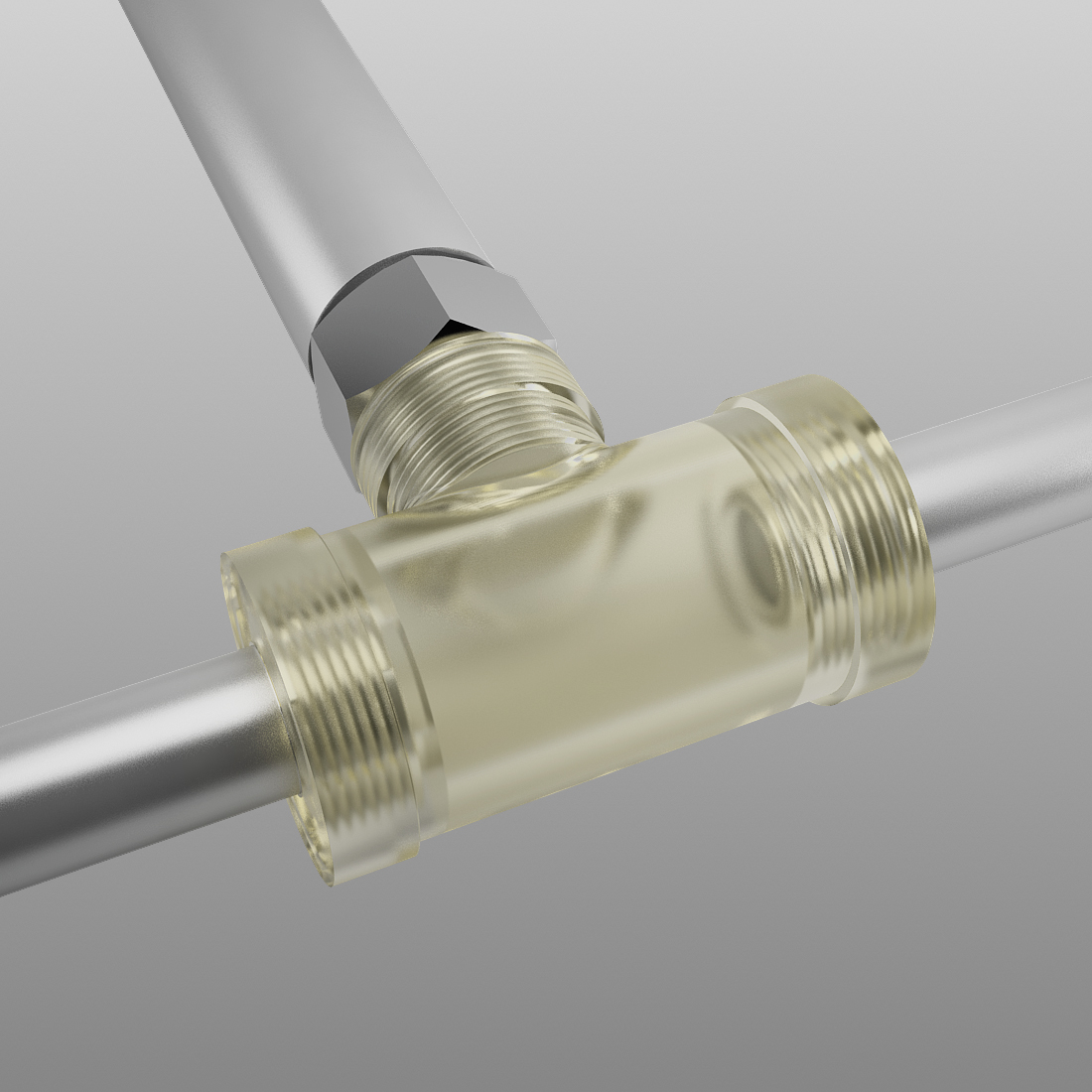

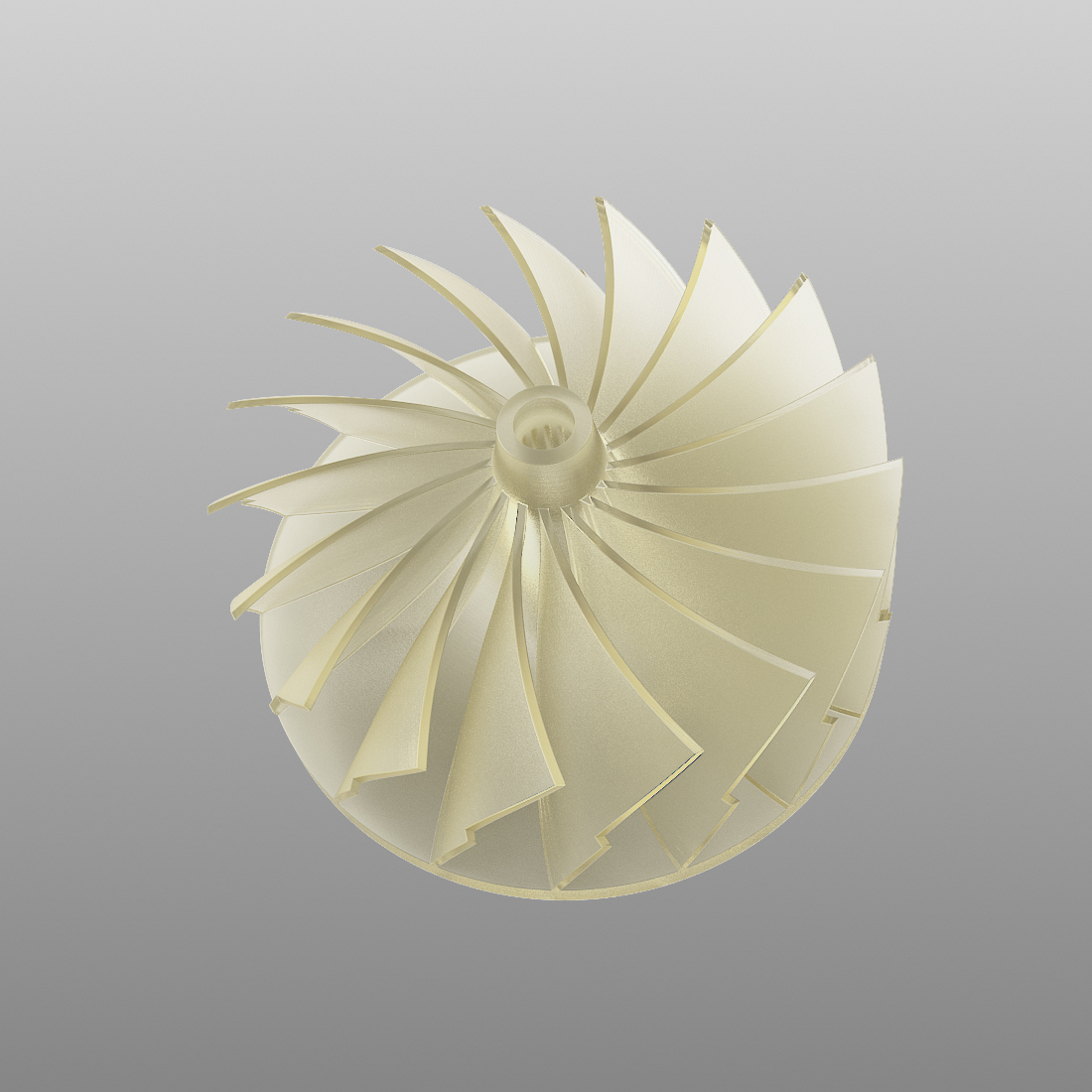

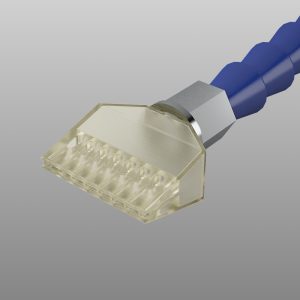

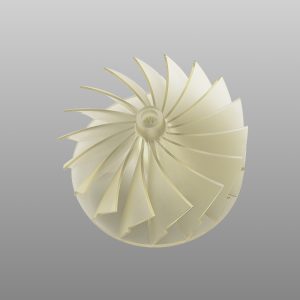

■ find out areas of air ducts where foreign bodies accumulate

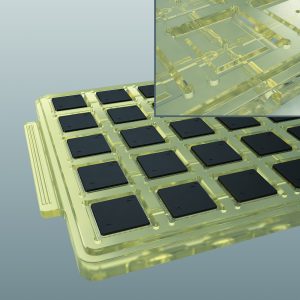

■ evaluate the heat-resistance of hardware with a ready mounted printed circuit boards

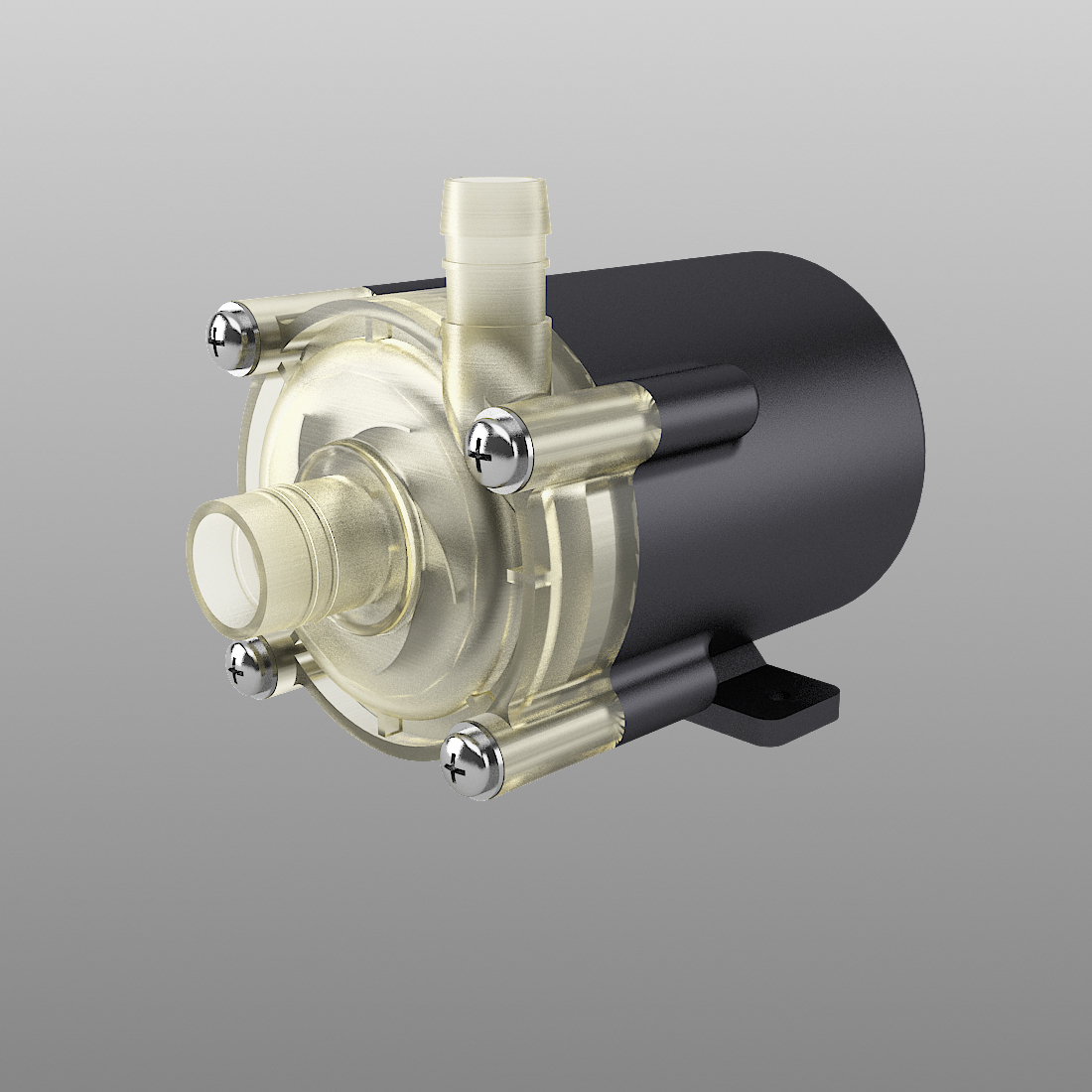

■ check if there are problems with oil flow caused by temperature fluctuations

form inspection…

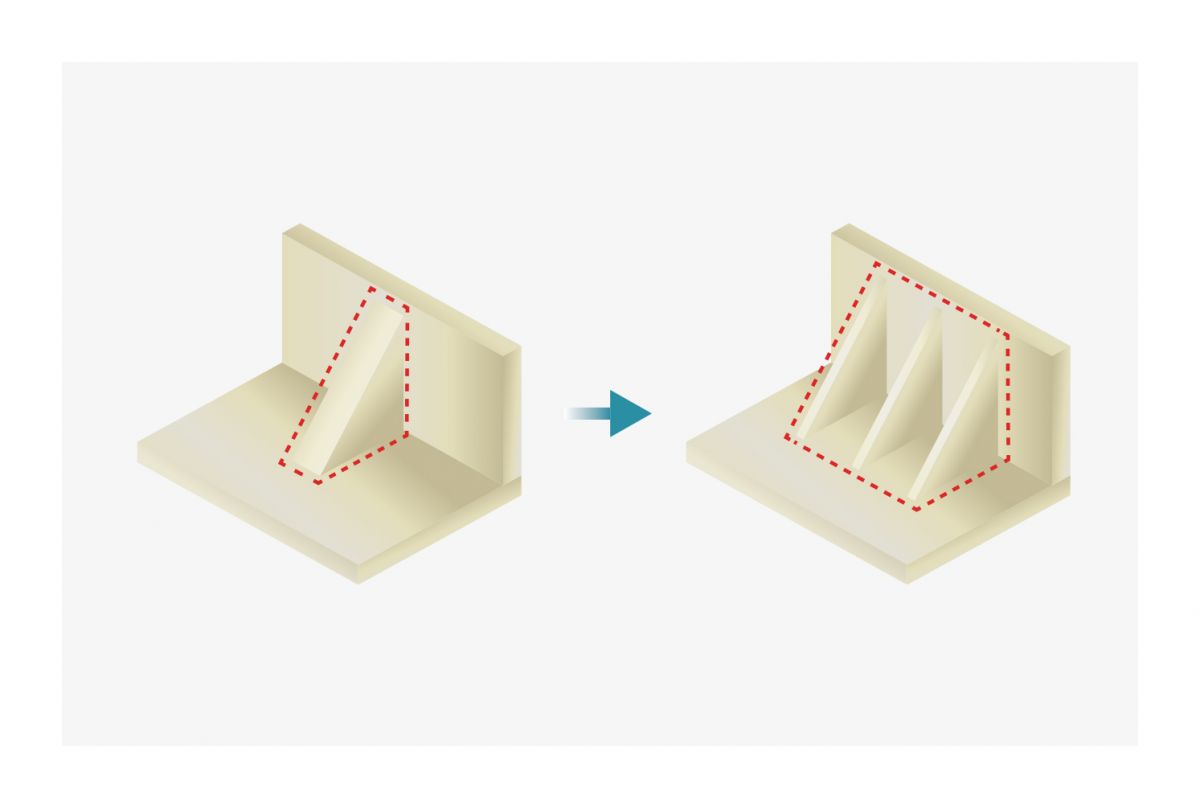

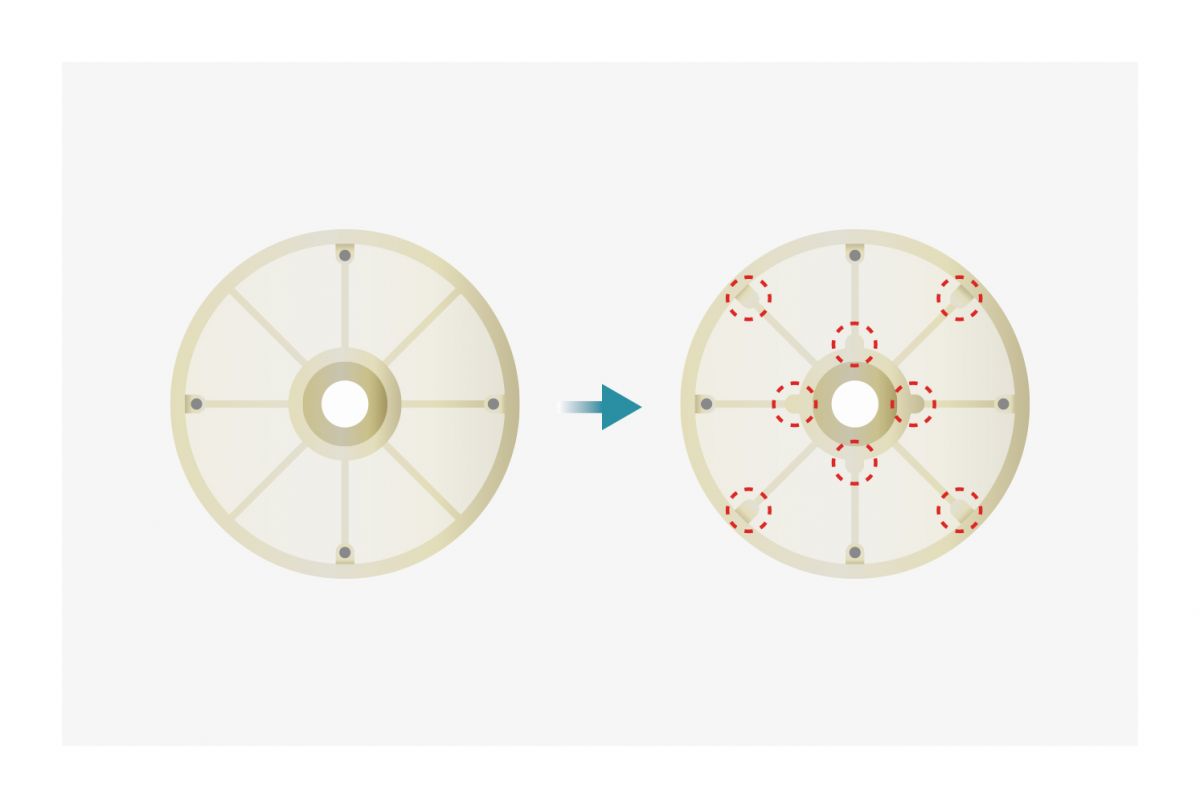

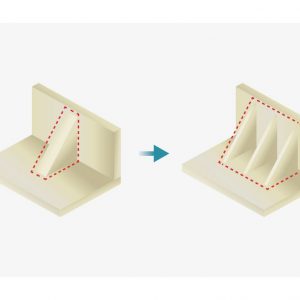

■ optimize strengthening ribs to avoid faulty workpiece shape

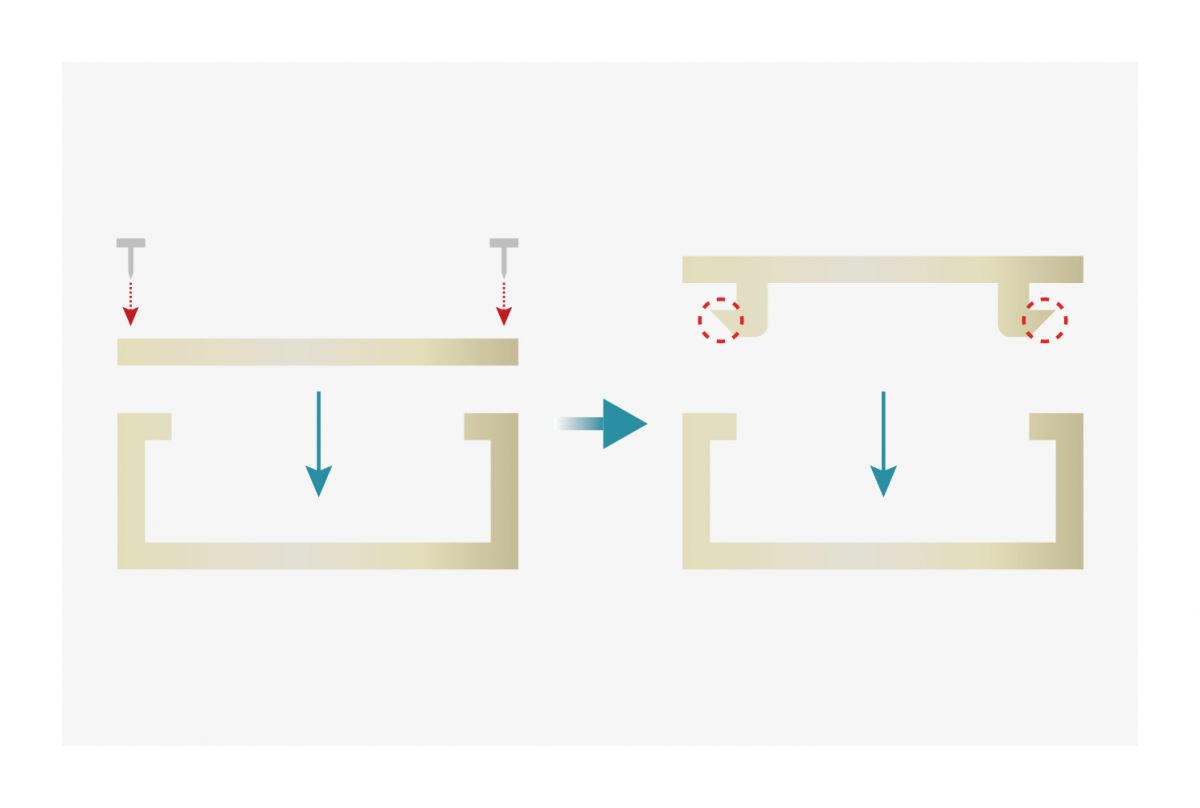

■ create appropriate thickness & suitable gas vents to avoid partial filling

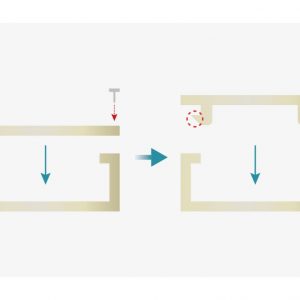

■ determine position & amount of ejector pins considering the product design

■ avoid sink marks by considering flow direction & altitude differences of the synthetic resin

■ optimize the position of the sprue cup to avoid welding seams

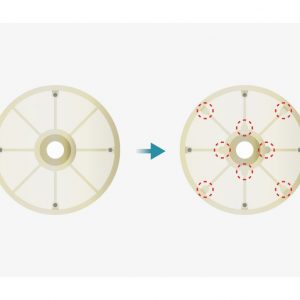

■ integrate CT-data to evaluate shrink-vulnerable areas

production preparation…

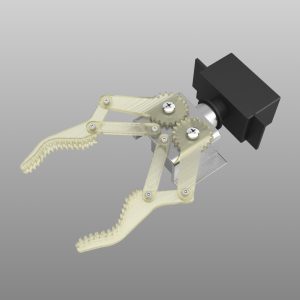

■ try different options e.g. for robot gripper jaws & find out the perfect gripper jaws for your product

■ test directly at the production line before producing the final prototype

■ determine the stability of products which have free-form curves

serial products and much more…

■ improve customer satisfaction with demo models

■ parts can be used as temporary production equipment

■ in cases of urgent needs create quickly fixtures for the evaluations of products

■ print your artwork or spare parts no longer available

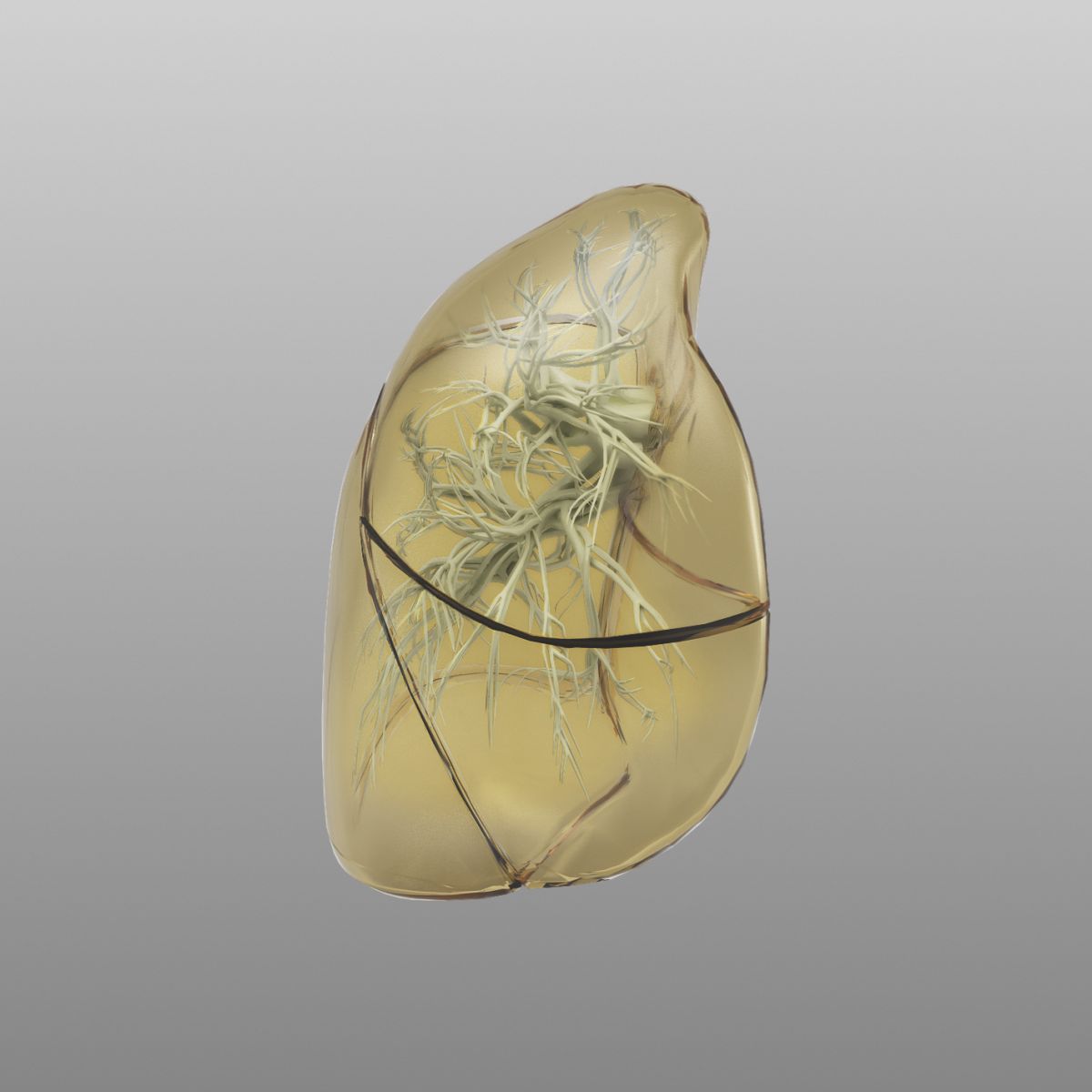

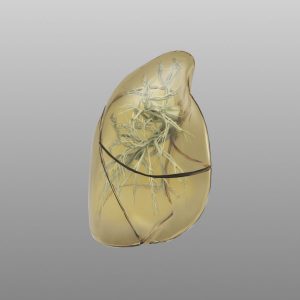

3d-print made of silicone

shore A hardness up to 65

- layer thicknesses with a resolution of 30 μm

- min. wall thickness starting from 0,3 mm / 0,011″

- printed models with resistance & characteristics of silicone

heat-resistent up to 200°C / 392°F

very thin-walled & elastical models possible

print precision on ultra-high level

construction part size length max. possible 210 mm (8,26″) x width 297 mm (11,69″) x height 200 mm ( 7,87″) possible

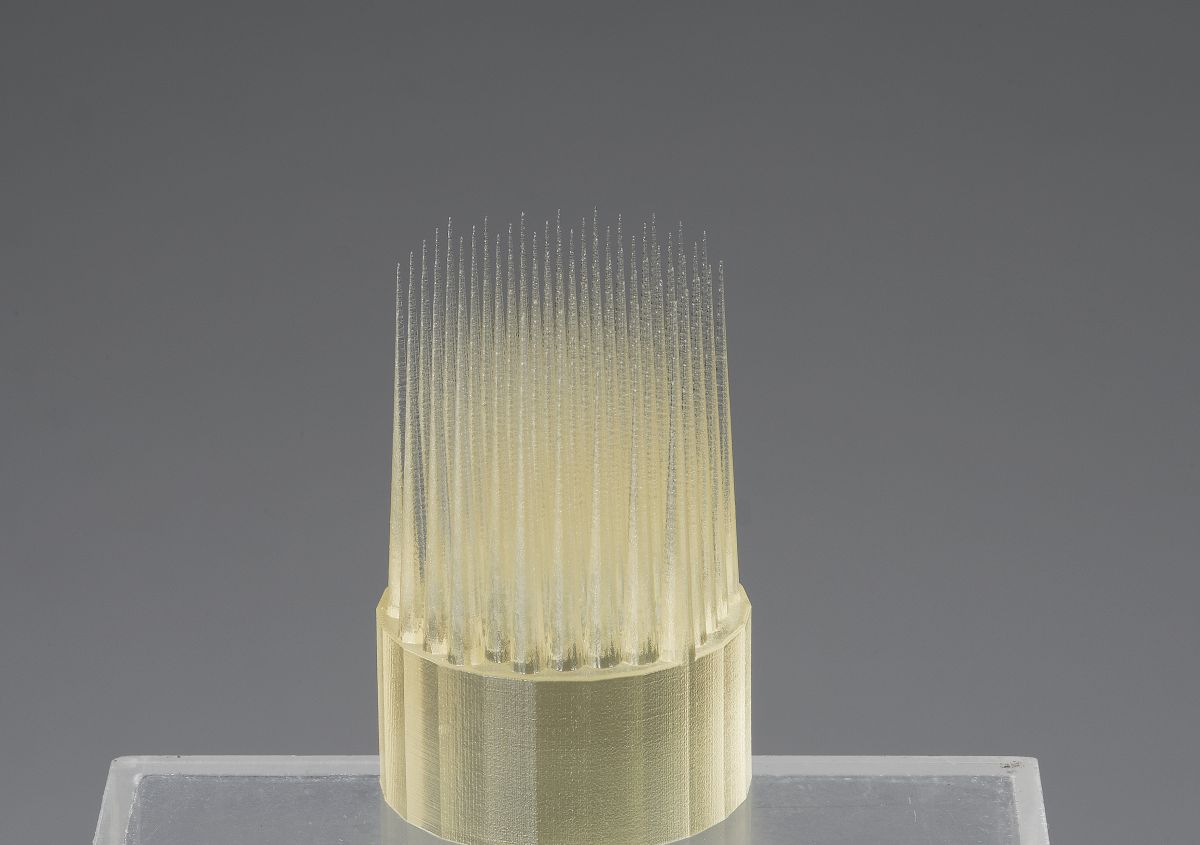

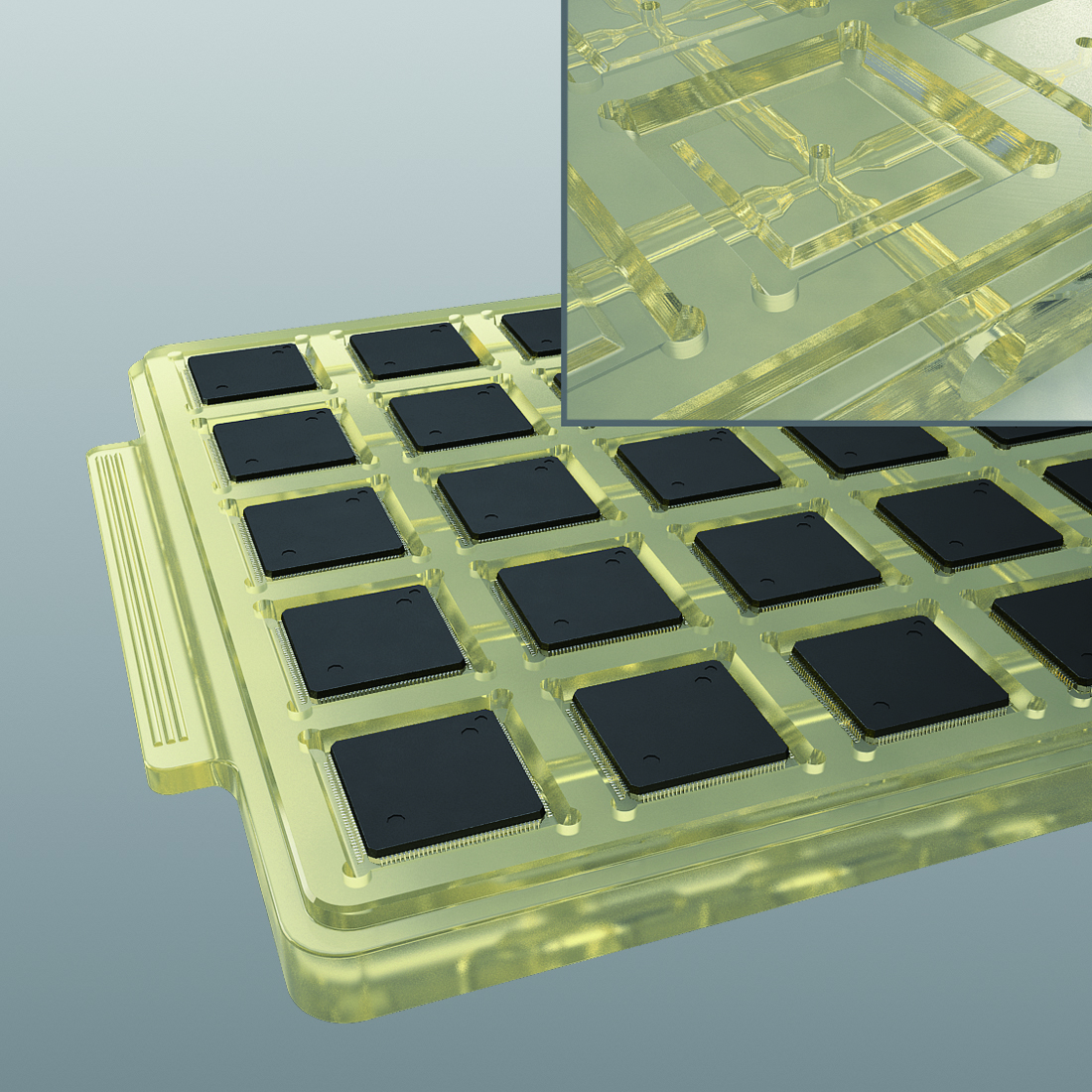

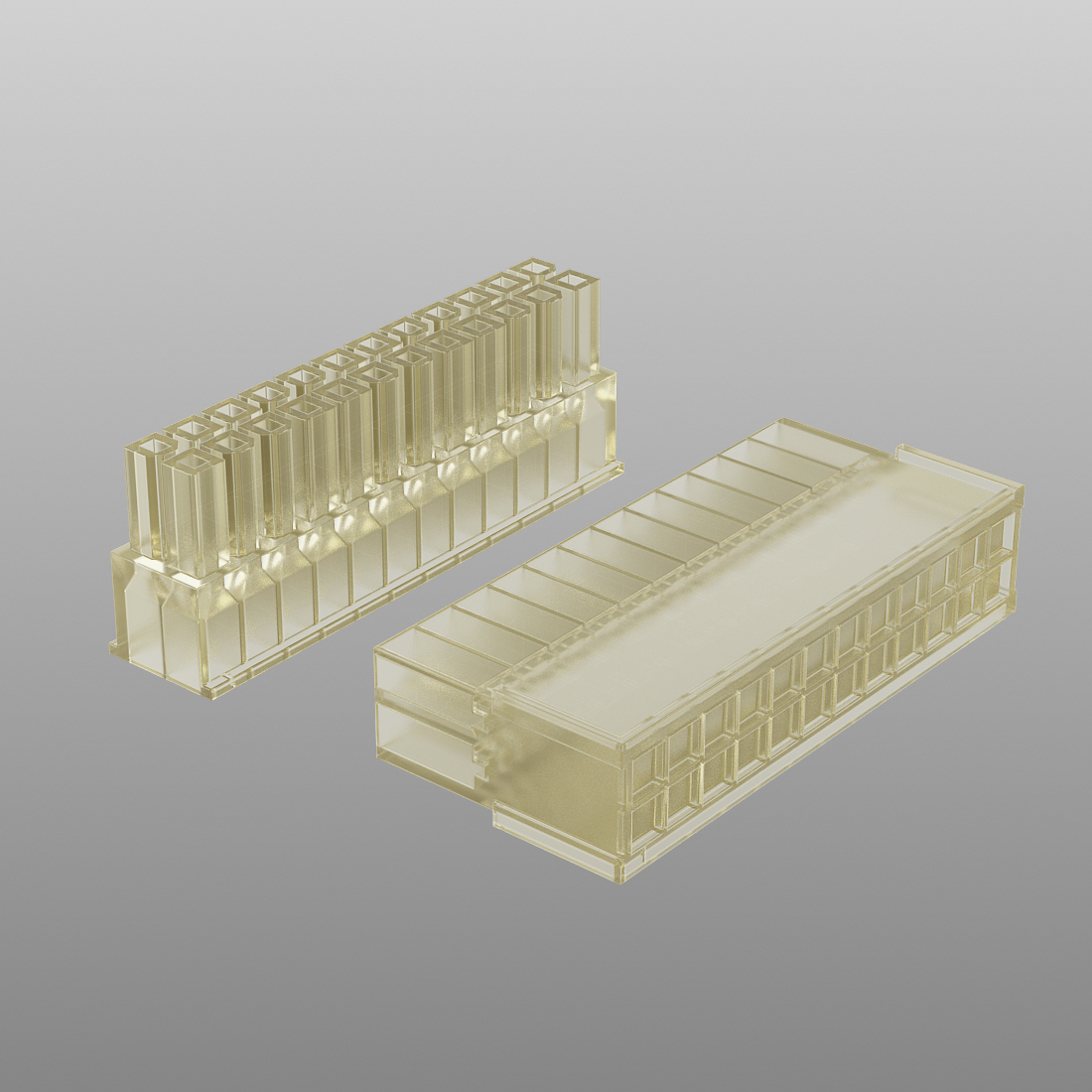

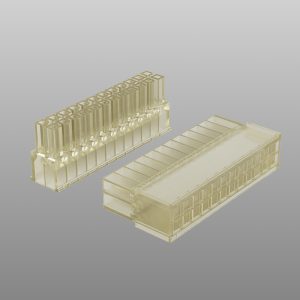

3d-print made of plastic

- layer thickness with resolution of 15 μm

- min. wall thickness starting from 0,3 mm / 0,011″

high stability: tear-resistant & break-proof

milk-glass or transparent print: assessment of internal structure possible

heat-resistent up to 103°C / 217,4°F

- long durability & form stability

print precision on ultra-high level

construction part size length max. possible 210 mm (8,26″) x width 297 mm (11,69″) x height 200 mm ( 7,87″) possible