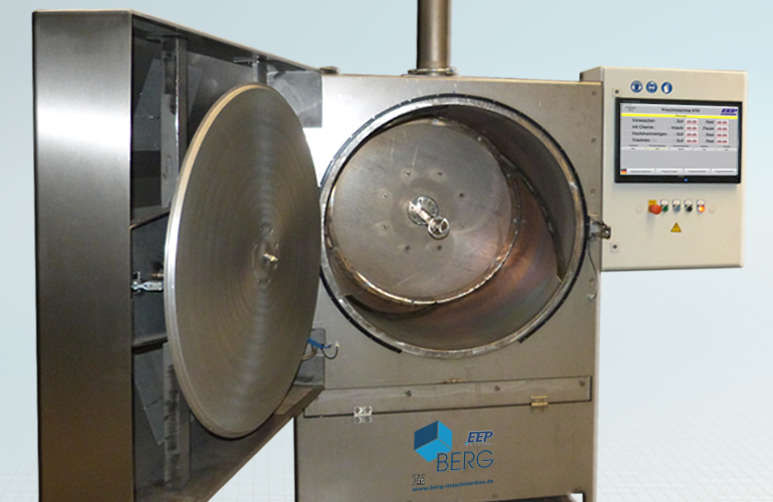

W90

special high-pressure washing & drying machine

High pressure washing machine for the effective cleaning of medical & technical elastomers with article dimensions up to 500 mm – no washing net required

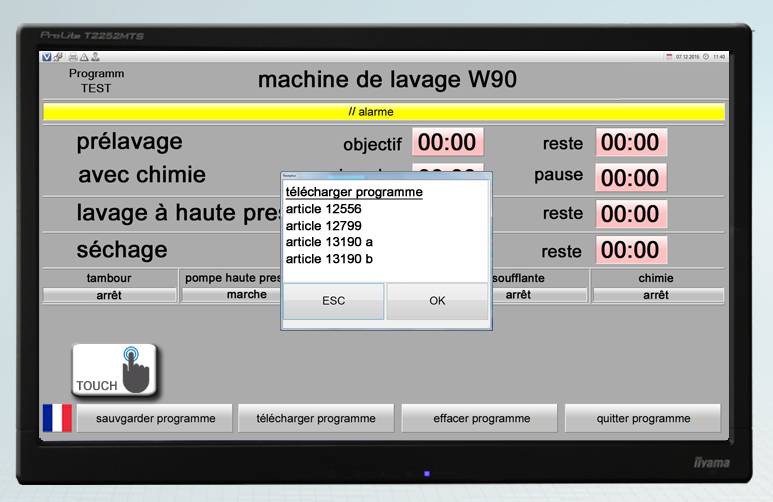

This machine provides high efficiency cleaning of medical and technical elastomers and is construed for big sized batch demands at high throughput. The W90 is, like any of our machines, designed for high performance with economic efficiency. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option.

For industry 4.0 demands, the W90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally.

By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible.

The W90 offers you maximum economic efficiency on treatment of big batch volumes at high throughput!

Kurzübersicht:

type of loading: manually

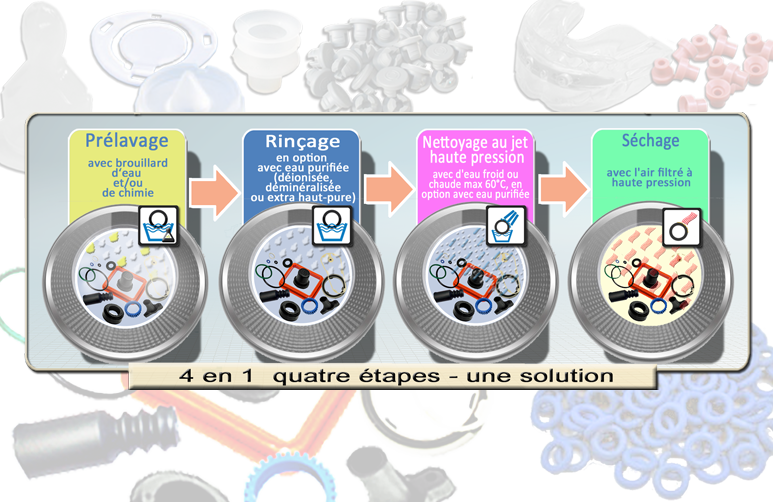

fast processing times (generally 10 – 35 minutes) at max. 60 l batch volume (volume and treatment time depend on geometry, dimension, material compound and degree of contamination of the moulded part to be treated)

washing cold or hot (max 60° C/140°F) – with or without chemicals possible

on option washing with de-ionized, de-mineralized or ultrapure water possible >upgrade installation also possible subsequently

drying with filtered high pressure air

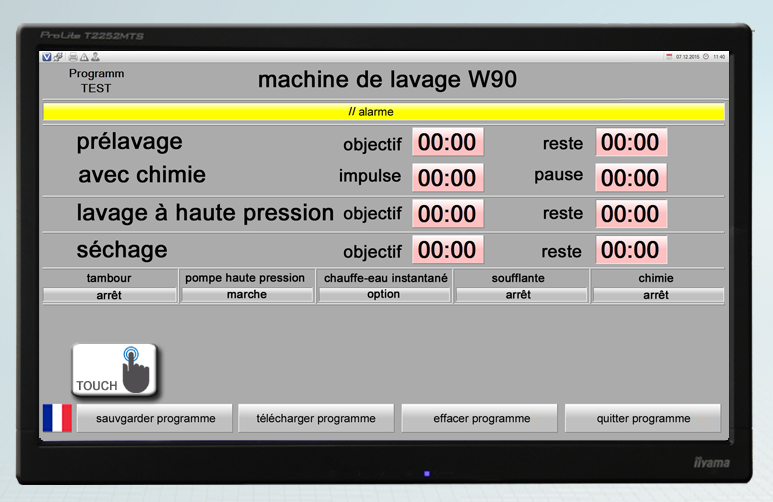

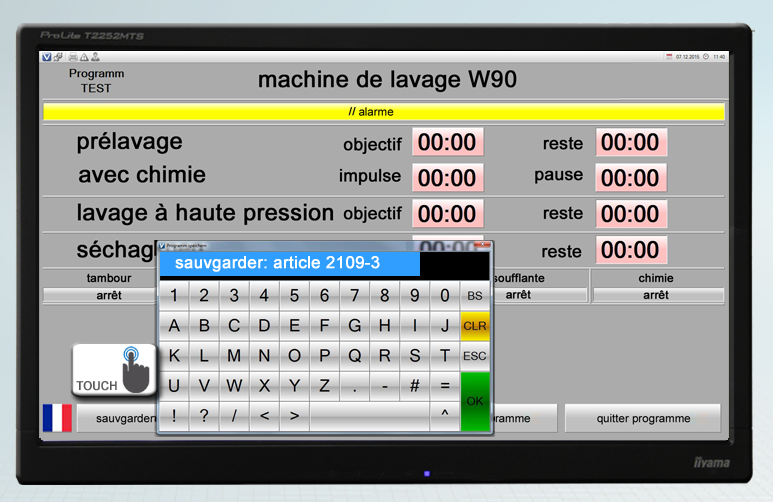

clear & comfortable 21,5″ touchscreen operation, USB and optional barcode scanner

recipes-memory & easy loading of your own processing parameters

individual user management: e.g. operator limitations, password query etc, on option user log-in via barcode scanner (e.g. ID card) or ID-key possible

logging, documentation & traceability of all machine events (data exportable via LAN/USB, Microsoft Excel compatible data)

network connection (fast technical support by internet connection possible, additional monitoring of the machine’s processing data from external place possible, on option: OPC-UA server for external machine control >> industry 4.0)

individual drum perforation available by choice

on option with siliconisation or similar coating additionally possible

standard detergent concentrate biodegradable

all motors & gears are located outside the wet area

clever designed construction >> unsusceptible operation >> good accessibility to machine components >> low wear-out level >> long durability

working level (peak) below 80 dB(A)