Test-deflashing service

Cryogenic test-deflashing of your molded articles

To evaluate whether your molded items are suitable for cryogenic deburring and how efficient and economical this process is for your unique needs, your molded items should undergo cryogenic test deburring.

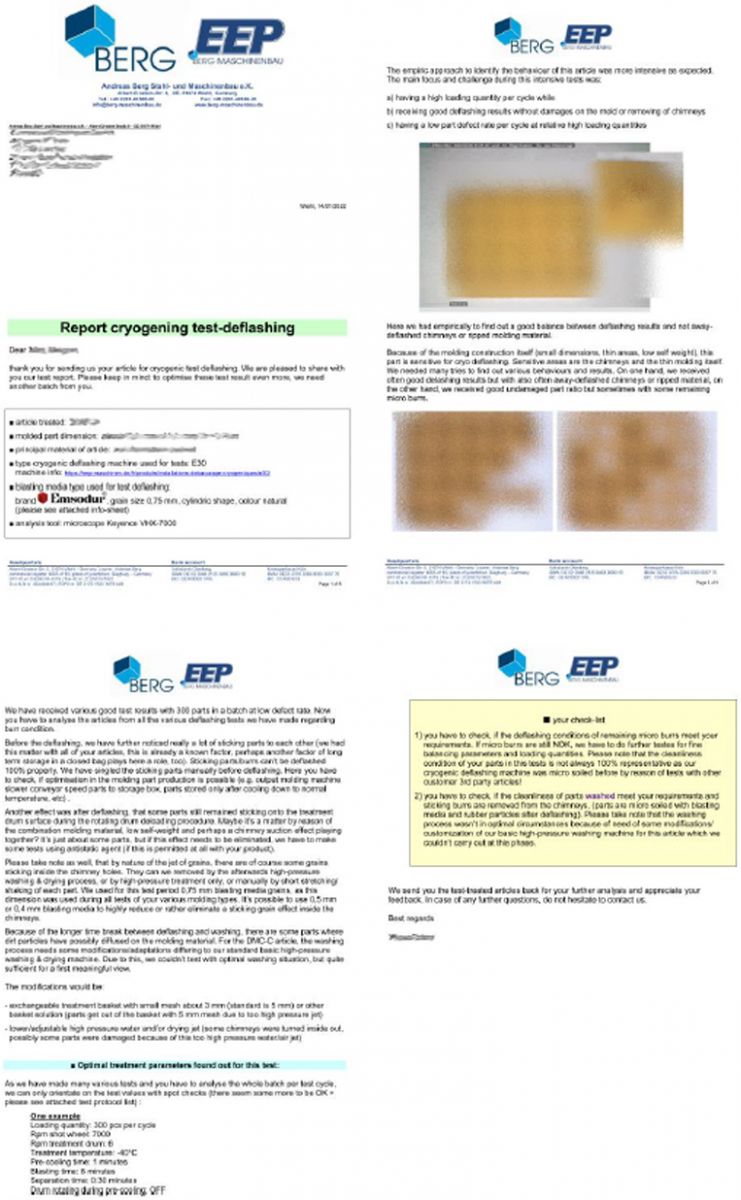

As there are countless variations of molded parts existing and several influencing factors play a role in the cryogenic process as well, your items must first run an empirical test series in a cryogenic deflashing system. The respective processing parameters and the possible processing quantity are very depending on the factors of burr condition, geometry, size and material properties of the molded article to be processed. The processing parameters and loading quantities can vary enormously depending on the molded part. Thus, a preliminary assessment of a deflashing result and the behavior of the molded article in the cryogenic process is not possible.

With the help of our test-deflashing service, you will receive a solid calculation basis for cryogenic finishing for your respective molded article, which will then also serve as the basis for a planned machine investment.

A prerequisite for meaningful cryogenic deflashing tests is supplying previously defined test quantities (usually test phase #1 with smaller quantities, test phase #2 then with larger quantities for around 5 – 10 consecutive processing cycles for each type of molded article).

Our cryogenic test deburring includes:

Empirical running-in of your respective article type on our cryogenic deflashing system

Evaluation of the behavior of your respective article type in the cryogenic deflashing process and its eventual special characteristics

Determination of whether the “cryo-rubbing” method can be used as an alternative (cryogenic deburring without need of blasting media by rubbing the deep-cold parts against each other) – per molded article

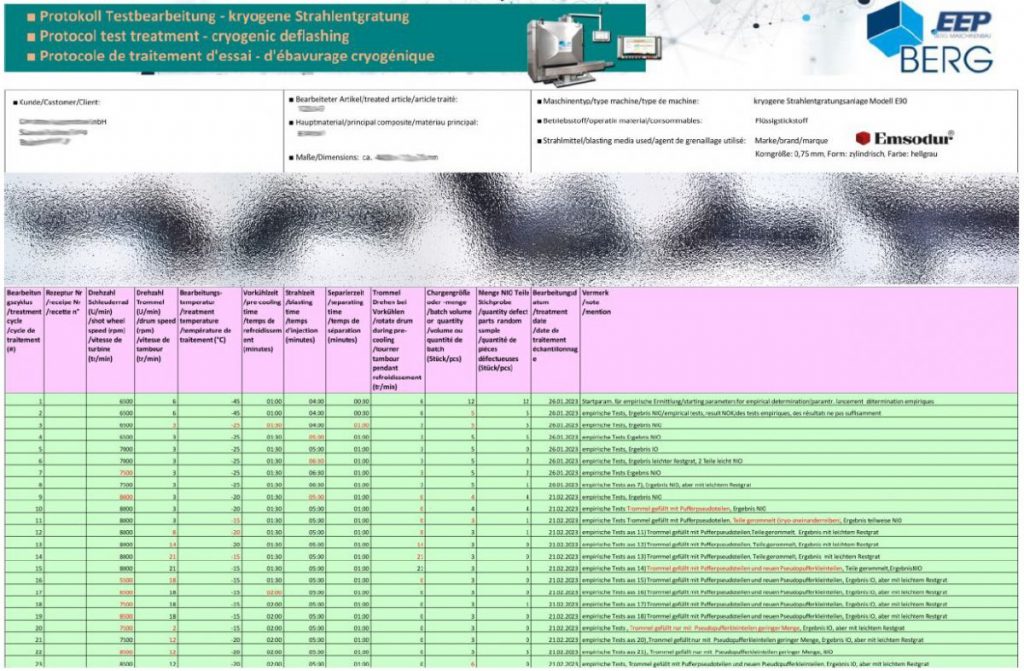

Determination of the optimal processing parameters – per molded article

Determination of the optimum loading quantity – per molded article

Determination of liquid nitrogen consumption per processing cycle and average consumption – per molded article

Evaluation of the deburring result – per molded article

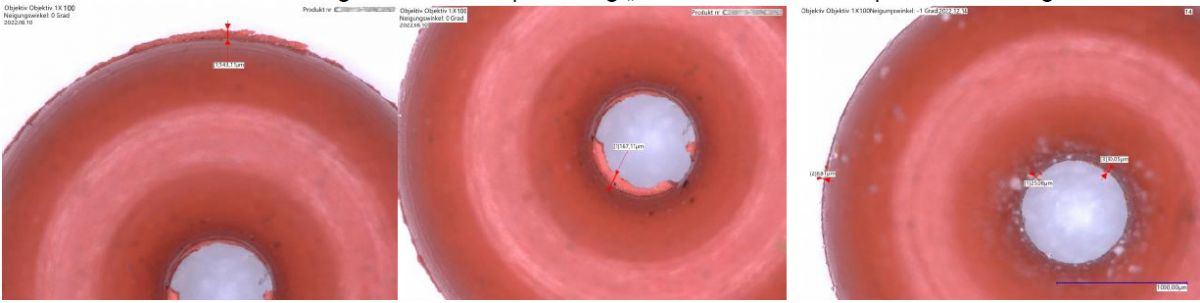

Microscopic measurement of burr status before and status afterwards (random samples) – per molded article – also possible: “Teams” video meeting with microscope live transmission

Test protocol with all test processing cycles (in German, English or French) – per molded article

Test completion report (in German, English or French) – per molded article

Video meetings (Teams/Skype) if there is a need for clarification

Creation of the optimal processing parameters for all previously test-processed molded articles (will be stored as a recipe in the machine) when purchasing one of our cryogenic deflashing systems

When buying a machine: % offsetting of the total test processing costs paid against the machine purchase price of one of our cryogenic deflashing systems (valid for a maximum of 6 months)

We are looking forward to receiving your inquiries!