Model E40

Cryogenic media-blasting deflashing machine – Size L

Cryogenic high-performance system for the efficient deburring of elastomers, plastomers, duromers, zinc die-cast and other thermally embrittling materials

suitabel for mouldings from 3 to 300 mm (0,12 to 11,81 inches)

Computer controlled cryogenic media-blasting deburring system, ideal for the treatment of batches up to 60 litres (13 UK gal) – fast treatment, secure and reliable!

Features:

**NEW** Additional liquid nitrogen surveillance: meet now even more security in the cryo-process

**NEW** Liquid nitrogen consumption measurement: per cycle, individual & total

**NEW** Liquid nitrogen input filter: stop troublemaking contamination from the supply pipe/nitrogen tank

Blasting-media circulation with internal drum screening

Blasting-media aspiration without need to open any door: no intrusion of warm ambience air

Recipe management: fast loading of your article treatment parameters – via barcode possible, too

Additional monitoring of complete process data from external working place – with OPC-UA possible, too

Nitrogen-application modified air circulation system with quick-exchange filterkit

Cryogenic chafing-deburring without need of blasting-media possible additionally

Self-regulating feedback screw for the optimal blasting-media flow

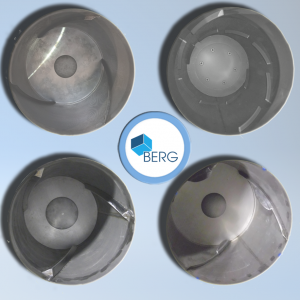

Drums availalbe with various drum perforations and drum mixing-fingers

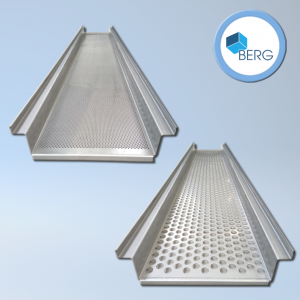

Deloading vibrating sieve with exchangeable screen topdecks and different types of screen perforations available

Deloading vibrating sieve with adjustable vibrating intensity (part of the article recipe as well)

Treatment of moulded articles up to 300 mm (11,81 inches)

Monitoring display of shot-wheel drive working in the blasting process

Machine operator limitations with user log-in freely configurable (admin/user)

Logging, documentation & traceability of all machine happenings and users

Treatment temperature up to -150°C (-238 °F) and shot wheel speed up to 8.000 rpm

optionally with exhaust air dome system to enhance non-optimal infrastructure at place of installation

Convenient 21,5″ Full HD touchscreen operation, Intel® Core i5 processor, SSD, USB & LAN

Shot wheel speed maximum 8.700 rpm with maximum ejection speed of 132,1 meter/sec. or rather energy per 1 cm²: 0,53 Joules/cm² – computation base at -75°C (-103 °F) and 0,75 mm (0,03 inches) blasting-media grain size

Reliable consistent machine performance guaranteed:

all motors & gears are located outside the freezing area, no risk of freezing blockades of drives!

low nitrogen consumption – high throughput – maximum economy

Ready for Industrie 4.0 – Cryogenic deflashing on the next Level!

Extensive possibilities – your QM will get excited!

21,5″ Full HD touchscreen operation for optimal work-flow, with extensive possibilities like recipe management (via barcode, too), user restrictions and password request, standby mode, N2 eco-blasting or QM compliant selectable, liquid nitrogen consumption display, logging, documentation, traceability of all happenings and users (CSV-data), signaling system, service manual mode and much more

Product diversity needs flexibility in the deburring process

In the cryogenic process, we face various needs with flexible solutions:

various vibrating sieve topdeck screens available

various types of vibrating sieve chutes available

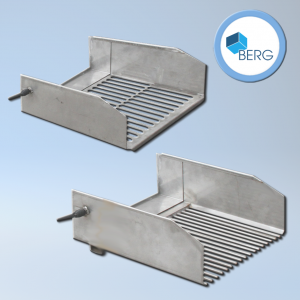

various types of mixing fingers available