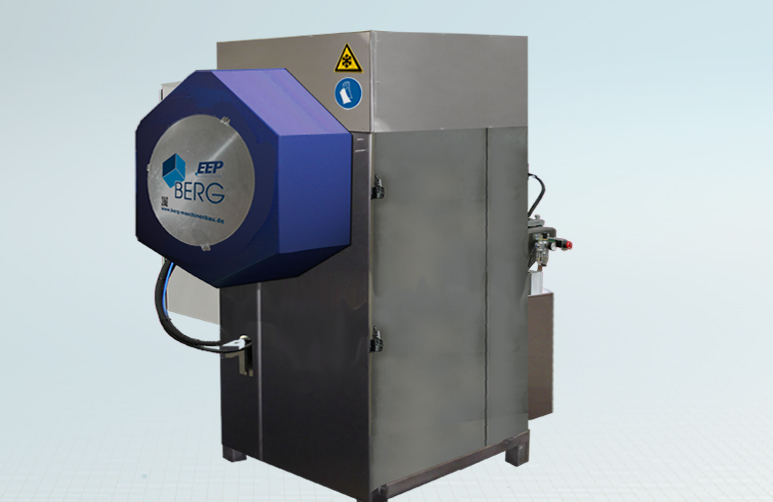

T10

small-sized cryogenic decoating machine for the removal of production-related elastomer adhesion – without use of chemicals

This machine offers high-efficient removal of production-related elastomer residues on metal and thermo/duroplatstic parts – without using chemicals.

With its small footprint, the compact machine can be integrated into the production line easily. This saves temporary storage or extra transports and finally corresponding time loss and costs.

The T10 is, like any of our machines, designed for high performance at low consumption of nitrogen and electric energy. The machine is especially designed for smaller batch needs.

This machine will be manufactured individually in accordance to the costomer needs!