W30

special high-pressure washing & drying machine

Special small-sized high-pressure washing machine for the efficient cleaning of medical & technical elastomers with article dimensions up to 150 mm – no washing net required

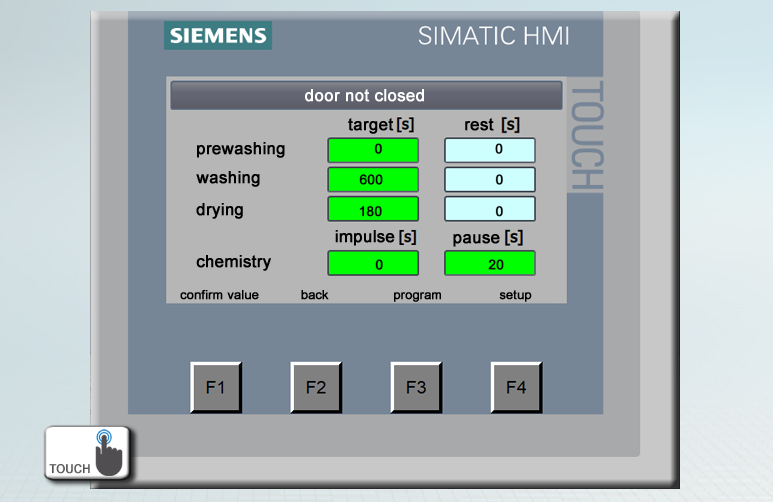

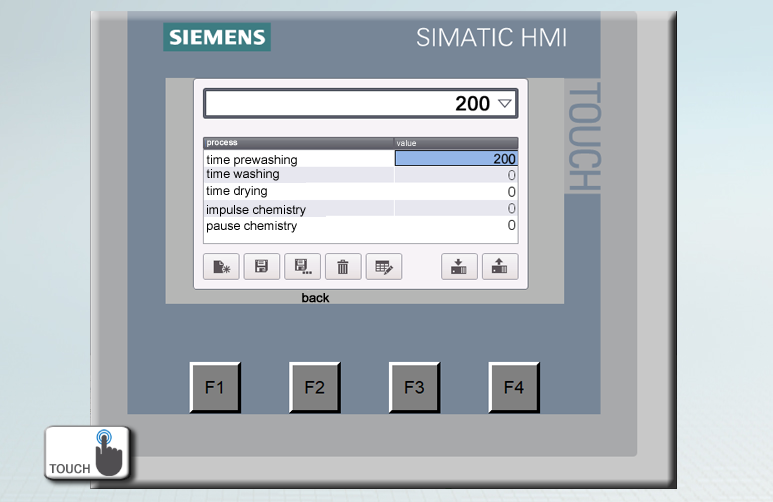

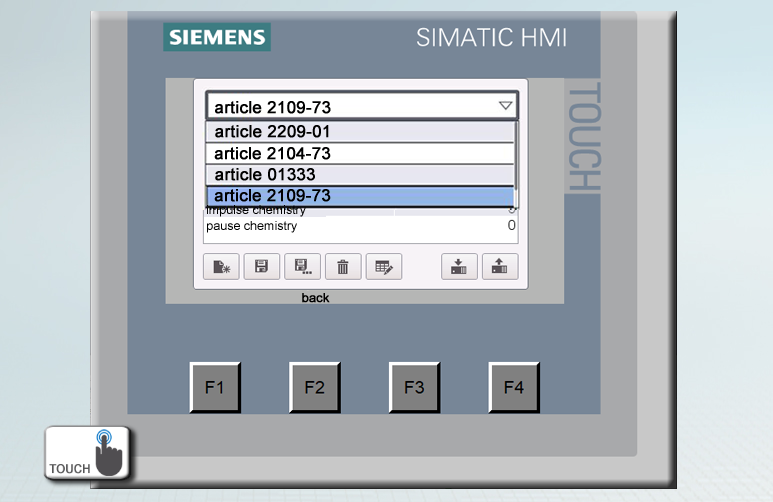

With its small footprint, the W30 can be integrated into the production line easily. This safes temporary storage or extra transports and finally corresponding time loss and costs. The W30 is, like any of our machines, designed for high performance with economic efficiency. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible.

Thanks to the exchangeable bastekt system, a fast and secure loading and deloading of each charge is ensured without the risk of having mixtures of similar-looking articles possibly. These interchangeable baskets are also compatible with our cryogenic deflashing machine E30W and furthermore optimally suited for a linear in-line processing → production → deflashing → washing → postcure tempering, as these loading baskets may be used compatible with each respective machine in the production line.

For industry 4.0 demands, the W30 is best prepared. An OPC-UA server for the total control and monitoring of the machine can be installed additionally on option.

By special request, siliconisation of rubber parts or coating with other glide agents is possible additionally.

With this small-sized machine, your treatment capacity is at best cost-performance ratio!