Model E40

Cryogenic media-blasting deflashing machine – Size L

Cryogenic high-performance system for the efficient deburring of elastomers, plastomers, duromers, zinc die-cast and other thermally embrittling materials

suitabel for mouldings from 3 to 300 mm (0,12 to 11,81 inches)

Computer controlled cryogenic media-blasting deburring system, ideal for the treatment of batches up to 60 litres (13 UK gal) – fast treatment, secure and reliable!

Features:

Reliable consistent machine performance guaranteed:

all motors & gears are located outside the freezing area, no risk of freezing blockades of drives!

low nitrogen consumption – high throughput – maximum economy

Ready for Industrie 4.0 – Cryogenic deflashing on the next Level!

Extensive possibilities – your QM will get excited!

21,5″ Full HD touchscreen operation for optimal work-flow, with extensive possibilities like recipe management (via barcode, too), user restrictions and password request, standby mode, N2 eco-blasting or QM compliant selectable, liquid nitrogen consumption display, logging, documentation, traceability of all happenings and users (CSV-data), signaling system, service manual mode and much more

Product diversity needs flexibility in the deburring process

In the cryogenic process, we face various needs with flexible solutions:

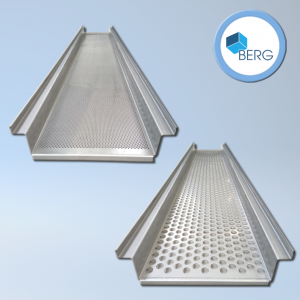

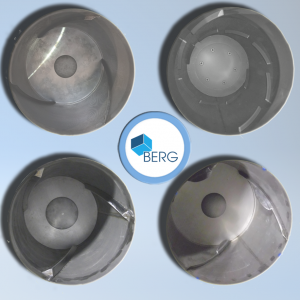

various vibrating sieve topdeck screens available

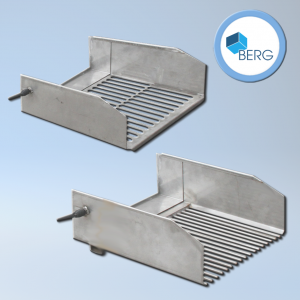

various types of vibrating sieve chutes available

various types of mixing fingers available